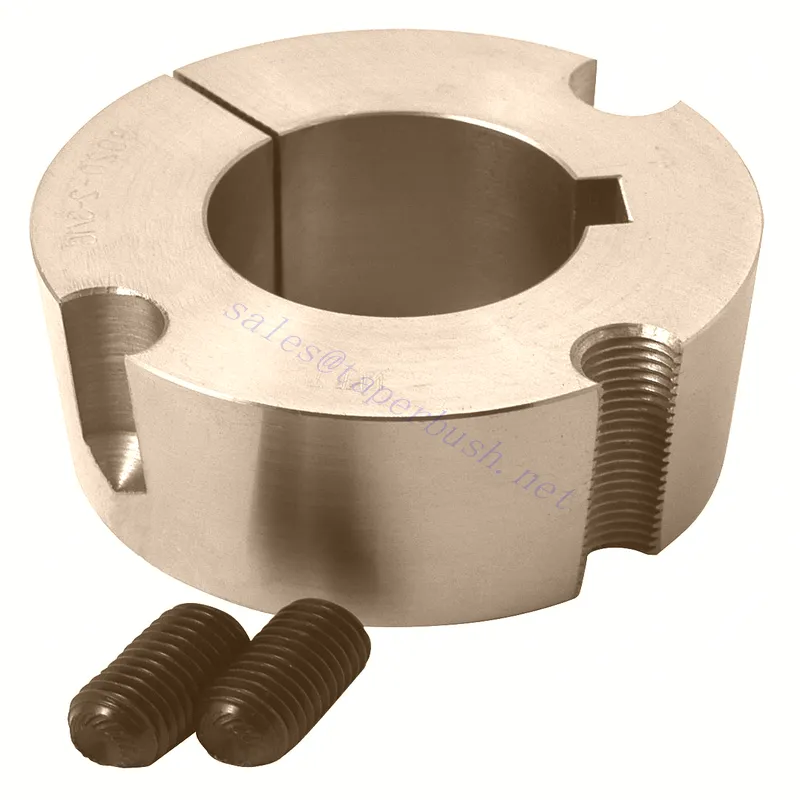

Taper Lock Bushing For Pulley

As one of the taper bushing manufacturers, suppliers, and exporters of mechanical products, We offer taper bushing and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of the taper bushing.

A) Taper Bush: 1008,1108,1210,1610,1615,2012,2517,3020,3030,3535,4030,4040,5050.

Different bores with keyways are available in metric and in inches.

B) Welding hubs for taper bushes

a. Taper type K weld-on hubs; b. Taper type W-WA weld-on hubs; c. Taper type F weld-on hubs;

d. Taper type S weld-on hubs; e. Taper type W weld-on hubs; f. Taper type WH weld-on hubs;

C) Taper adapters

1215B, 1615B, 2517B, 2525B, 3030B, 3535B, 4040B, 4545B

(Note: Stanard for taper bushing weld-on hubs adpot USA DODGE Co. and Martin standard. Any production and sales should be

authorized. )

D) Taper bored bolt-on hubs

SM1210, SM1610-1, SM1610-2, SM2012, SM2517, SM30-1, SM30-2;

E) XT Bushing

XTB15, XTB20, XTB25, XTB30, XTB35, XTB40, XTB45, XTB50, XTB60, XTB70, XTB80, XTB100, XTB120.

F) XH hubs

XTH15, XTH20, XTH25, XTH30, XTH35, XTH40, XTH45, XTH50, XTH60, XTH70, XTH80, XTH100, XTH120;

XTH15F4, XTH15F5, XTH15F6, XTH15F8; XTH20F5, XTH20F6, XTH20F8, XTH20F10, XTH20F12; XTH25F6, XTH25F8, XTH25F10, XTH25F12;

G) Split taper bushings

G, H, P1, P2, P3, B, Q1, Q2, Q3, R1, R2, S1, S2, U0, U1, U2, W1, W2, Y0.

H)Steel hubs for split taper bushings

HG1, HH1, HCH1, HP1, HCP1, HP2, HB1, HB2, HQ1, HCQ1, HQ2, HR1, HR2, HS1, HS2, HU0, HU1, HU2, HW1;

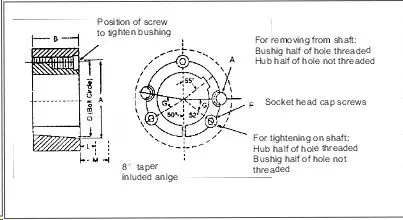

| Bushing Specifications and Dimensions(inches) | ||||

| Bushing No. | A | B | D Bolt Circle | Wt (Apx.)lbs. |

| 1108 | 1.511 | 7/8 | 1 29/64 | 0.33 |

| 1210 | 1 7/8 | 1 | 1 3/4 | 0.61 |

| 1215 | 1.875 | 1 1/2 | 1 3/4 | 0.8 |

| 1610 | 2 1/4 | 1 | 2 1/8 | 0.9 |

|

1615 |

2.25 | 1 1/2 | 2 1/8 | 1.2 |

| 2012 | 2 3/4 | 1 1/4 | 2 5/8 | 1.7 |

| 2517 | 3.375 | 1 3/4 | 3 1/4 | 3.5 |

| 2525 | 3 3/8 | 2 1/2 | 3 1/4 | 4.9 |

| 3020 | 4.25 | 2 | 4 | 6.5 |

| 3030 | 4 1/4 | 3 | 4 | 9.2 |

| 3535 | 5 | 3 1/2 | 4.83 | 14 |

| 4040 | 5 3/4 | 4 | 5.54 | 22 |

| 4545 | 6.375 | 4 1/2 | 6.13 |

30 |

| 5050 | 7 | 5 | 6.72 |

38 |

| Bush.No. |

Bush torques |

screw tightening torques | ||

|

Torque Capacity |

Wrench Torque | |||

| 1bf.in | N.m | 1bf.in | N.m | |

| 1008 | 1200 | 136 |

55 |

5.6 |

| 1108 | 1300 |

147 |

||

| 1210 |

3600 |

407 | 175 | 20 |

|

1215 |

||||

| 1310 |

3850 |

435 |

¡¡ | 20 |

| 1315 | ||||

| 1610 | 4300 | 486 |

175 |

20 |

| 1615 | ||||

| 2012 | 7150 | 808 | 280 | 31 |

| 2517 |

11600 |

1310 |

430 |

48 |

| 2525 |

¡¡ |

|||

| 3020 |

24000 |

2710 |

800 |

90 |

| 3030 | ||||

| 3535 | 44800 | 5060 | 1000 |

112 |

| 4040 | 77300 | 8740 | 1700 | 170 |

| 4545 | 110000 | 12400 | 2450 |

192 |

| 5050 | 126000 | 14200 | 3100 | 271 |

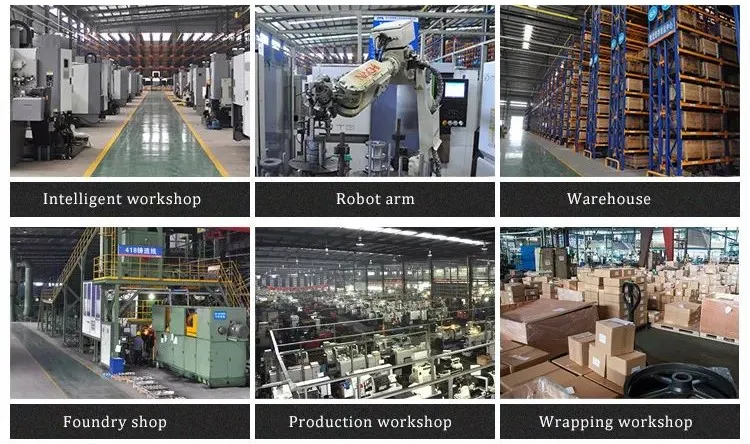

Factory Display

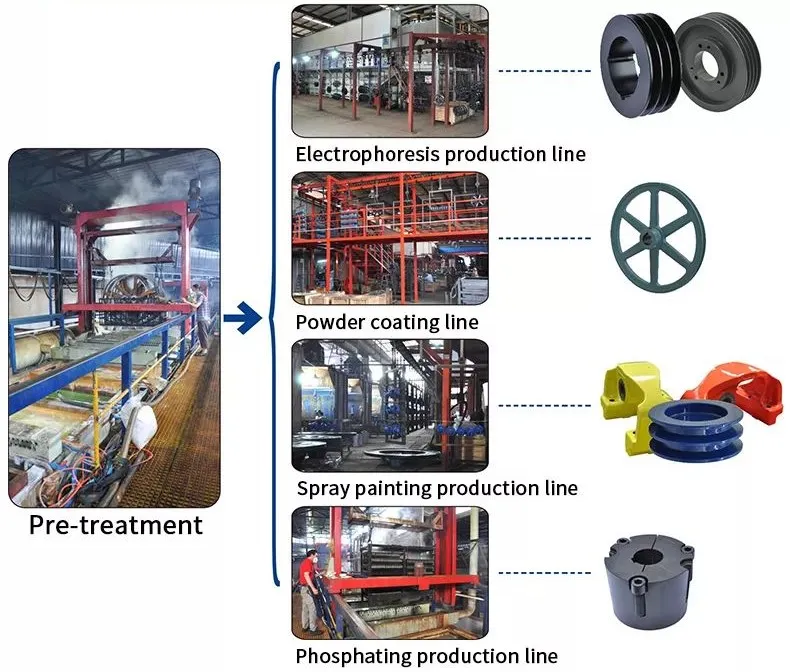

Surface Treatment

Machining inspection equipment includes CMM, roughness tester, projector, gear testing center, torque testing machine,durability testing machine, loading test bed, Tensile strength tester, noise tester and so on.

Workshop Equipment

Heat treatment testing equipment includes precision metallographic microscope, Vickers hardness tester, Brine-ll hardness tester, Rockwell hardness tester, portable hardness tester, electron potentiometer, salt spray tester, Magnetic particle flaw detector, thickness tester, etc.

Inspection Equipment